MULTICORE TUBES

MULTICORE TUBES

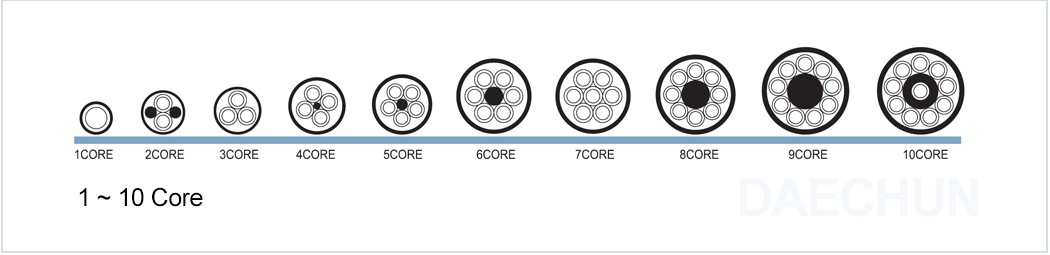

Multicore tubes efficiently connect installation, maintenance and control at the same time. They are made of stainless steel, cunifer or copper.Multicore tubes efficiently connect installation, maintenance and control at the same time. They are made of stainless steel, cunifer or copper, with a total of 10 tubes in the bundle, and other tube dimensions from 6 to 15 mm or from ¼” to ½” – up to the maximum operating pressure of 440 bar.

They are used mostly in shipbuilding, offshore plants and for liquid, gas or electricity transport.

- reduction in installation time and saving space in the tube bundle

- multiple reduction in the number of tube seams, as well as installation time and seams inspection

- saving space and simple design for easier bending in any direction – up, down, left, rightli>

- triple protection of outer tubes and effective protection against mechanical damage

- simple solution of the tube corrosion problem compared to conventional tubes which are exposed to sea water and shipyard environment

Multicore tubes are most commonly used in shipbuilding for:

- remote control systems for hydraulic and pneumatic valves in cargo tanks, ballast tanks and service tanks

- remote control systems for on deck equipment such as winches

- fixed gas detection system

- control of instrumentation, sampling and return line systems

- tank liquid level measurement system

- CO2 system or dry powder fire prevention system

304, 316, 316L, 317L, 321, 347, 904L, 6 Mo, Monel 400, Nikal 200, Inconel 600, Inconel 625, Inconel 825, Hastelloy C22, Hastelloy C276, Duplex, Super Duplex, Copper, Cu-Ni 90 / 10

Covering materials

PVC, PVC TCR, FR PVC, HFFR TPU, HFFR PE, PEHD, MDPE, LDPE, XLPE, multicore tube types are approved by all renowned classification companies such as ABS, DNV-GL, BV, CCS, Lloyd's, KR, RINA, RMRS, CRS and come with a several years of warranty.